This section contains brief discussions of various ballistics and shooting related topics as requested by correspondents. If you have a question you have been trying to find an answer to (keep 'em ballistics and shooting related--see your minister for the mysteries of life) email me by clicking here and I'll do my best to find the answer for you and if it is of general interest, publish it here. If you can contribute additional input to one of the answers I'd would appreciate hearing from you too.

Check back frequently as new topics are always being added.

On this page:

Q. What does "detonation" mean and can it happen with small arms ammunition?

A. There have been 2 common but improper uses of the word "detonation" among shooters. The first meaning simply refers to the normal action of the propelling charge. The second meaning is an apparently severe or destructive action of the charge. However, in long established technical usage, "detonation" means a highly distinctive kind of explosion different from either of the above.

After decades of study and instrumented test, the functioning of explosives and detonation is understood in considerable depth.

Typical smokeless powder propellants burn at and very near the surface. The speed at which the burning surface moves inward depends partly on composition of the propellant and any deterrent coating, and more on temperature and pressure. It varies from about 0.5 f/s for high energy solid propellants at about 2000 psi to about 5 f/s at typical firearms pressures, although such burning or deflagration as it is called, can proceed at pressures well above 100,000 psi. A large amount of gas is formed and flows away from the burning surface.

On the other hand a detonation, if started under proper conditions and with sufficient intensity, spreads with great speed. There are two conditions necessary for detonation. When they are met, an extremely thin shock wave moves through the explosive, followed closely by a somewhat thicker chemical reaction zone and then by the reaction products. The products move in the same direction as the detonation, a characteristic of detonation contrasting it with deflagration in which the reaction products flow away from the burning direction. In typical high explosives the speed of the detonation is 15,000 to 27,000 f/s, and the pressure in the reaction zone is 1,000,000 to 2,000,000 psi. This great speed and pressure varies somewhat with outside conditions but its order of magnitude is always the same.

Except in certain primary explosives, a detonation is not easily achieved. In practice the initiator must have comparatively great sharpness and be correctly placed, if the explosion is not to fall short of detonation or even fail entirely. The explosive must be packed to at least a minimum density throughout to propagate the detonation. In general any high energy material can be detonated; but it is the necessary conditions that may be difficult.

Attention has been given to the question as to whether detonation is possible in a small arms cartridges. The general opinion of authorities who have investigated the matter thoroughly has been that it is not. It appears that under the conditions in the cartridge, the explosive column is too short for the reaction to gain enough speed to make the great leap over to detonation. The possibility has been considered of detonation from some radical alteration in state of the charge, such as pulverizing from brittleness in extreme cold, but even then the gun would give way long before a detonation could be reached. In any case, no case of detonation of a small arms cartridge has ever been established so far as is known.

When discussing firearms pressures it would be convenient to have some single word for an unusually steep pressure rise, but "detonation" is not that word, if the user desires his report to be considered with respect.

Extracted from an letter by E. H. Harrison to the author and which was published in a somewhat modified format in the June 1965, American Rifleman

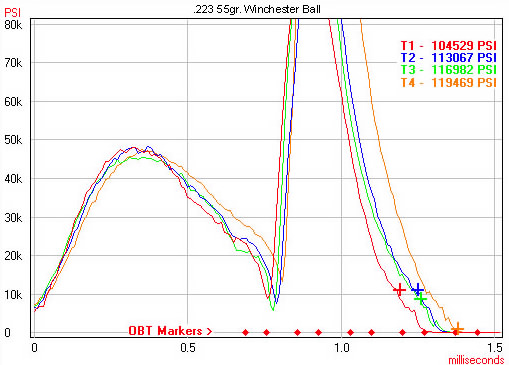

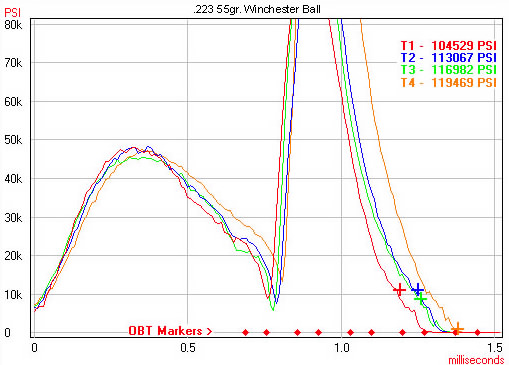

There has also been an observed phenomena in rifle ammunition with too slow a powder for the bullet weight or to light a bullet for the powder where an extremely high pressure spike occurs down the bore. While the exact mechanism of this effect is unknown it is believed than the bullet gets blown down the bore before full ignition has been accomplished. During this the deterrent coating on the powder gets burned off and the burning characteristic of the grains change and then ignite. Most pressure measuring device won't show this effect because of their low sample rate. It is visible with PressureTraceTM and has be confirmed by the folks at Vihtavoiuri.

With respect to the alleged "2.7 gr of Bullseye" powder detonation, the NRA and HP White laboratories investigated this and concluded that the damaged firearms were due to a combination of double or triple charging and a too deeply seated bullet. The results were published in the Armerican Rifleman in the December 1978 issue in an article titled More Facts On Chamber Pressure - The 2.7 gr Bullseye Blow-Ups, by W.C. Davis, Jr.

Q. What are the ballistic coefficients for lead round ball projectiles?

A. To properly describe the ballistic qualities of round projectiles you really need to use the GS drag model. Since most ballistics programs do not work with the GS function I have converted the GS to approximate G1 BCs.

| Caliber | Approx Weight Pure lead |

Diameter | GS | G1 |

| 32 | 47 | .315 | .068 | .037 |

| 36 | 65 | .350 | .076 | .041 |

| 38 | 80 | .375 | .081 | .044 |

| 40. | 92 | .395 | .084 | .046 |

| 45 | 127 | .440 | .094 | .051 |

| 50 | 175 | .490 | .104 | .057 |

| 54 | 235 | .535 | .117 | .064 |

| 58 | 284 | .575 | .123 | .067 |

| 62 | 325 | .600 | .129 | .070 |

| 70 | 495 | .690 | .149 | .081 |

| 72 | 550 | .715 | .154 | .084 |

Note: Using the incorrect G1 model yields between about 12 and 25 percent less drop depending on the range than the correct GS model as can be seen from the table below. Data based upon a .58 caliber round ball at 1200 f/s. 1" sight line.

| GS Drag Model | G1 Drag Model | |||

| Range (yds) | Vel (f/s) | Path (in) | Vel (f/s) | Path (in) |

| 0 | 1200 | -1.00 | 1200 | -1.00 |

| 50 | 985 | 4.01 | 1009 | 3.75 |

| 100 | 833 | 0.00 | 901 | 0.00 |

| 150 | 718 | -16.59 | 820 | -14.46 |

| 200 | 627 | -50.11 | 754 | -41.85 |

| 250 | 551 | -105.87 | 696 | -84.55 |

| 300 | 487 | -190.43 | 643 | -145.25 |

Q. What do you mean by learning the "Manual of Arms?"

A. While the common meaning generally refers to rifle drill (present arms; right shoulder arms, etc), in the modern technique it refers to the operation, and care of a firearm and it is part of the triad of marksmanship, gun handling, and mindset. To be a proficient shottist one should be able to operate the firearm (load, actuate its controls, and know its modes of carry), know how it operates and any operational quirks, be able to clear routine malfunctions and stoppages, and to disassemble and maintain it. You must also know the firearm's zero and trajectory. You should become so familiar with your firearm(s) that you don't have to give any conscious though to these things.

Q. How much does using a Ransom Rest decrease group size when testing handguns?

A. The answer depends a lot on the skill of the shooter. When used with revolvers or fixed barrel pistols the accuracy you get from the rest is pretty much dependent on the ammunition. However, when used with reciprocating slide autopistols the results can be less than what one would like unless the pistol is fitted very tightly which can effect reliability. Due to small random displacements in the slide/barrel on the frame the group size can increase because the pistol is aligned by the frame. Frequently autopistols will show better accuracy fired over a sandbag or off hand by a good shooter using the sights than from a Ransom rest.

As an example, a friend and I once experimented with a well worn GI 1911. I tightened the barrel to slide fit a little bit but left the slide to frame fit deliberately "GI" loose. Over a sandbag, my friend who was a member of the "Presidents Hundred" shot 2.2" groups at 25 yd using his practice ammo. When using the Ransom Rest the gun would only shoot about 4.5" groups. We then fitted a National Match barrel to the pistol in the same manner and only minimally tightened the slide/frame fit (There was still a little slop in the vertical.) This time the pistol shot 1" groups at 25 yd over sand bags and 2.9" groups from the Ransom Rest. With the slide tightened to the point of no noticeable slop in the vertical or horizontal it shot under 1" from the sand bag and 1.2"ish from the Ransom.

Q. Who invented the "Foster" shotgun slug?

A. The Foster slug was invented by a Karl Foster around 1931. It is characterized its deep hollow base design which places the center of mass very near the tip of the slug, much like a badminton shuttlecock. If the slug begins to tumble in flight, body drag will tend to push the slug back into straight flight. This gives the Foster slug stability and allows for accurate shooting out to ranges of about 75 to 100 yd, depending on the barrel Most Foster slugs also have "rifling" that consists of thin fins pressed into the outside of the slug. Contrary to popular belief, these fins do not impart any spin to the slug as it travels through the air, because the slug's passage through the air pushes a shockwave ahead of it that creates a vacuum on the side of the slug, where the fins are located. The actual purpose of the fins is to allow the slug to safely be swaged down when fired through a choke, although accuracy will suffer when such a slug is fired through tighter chokes. While designed for smooth bore barrels they can be used in rifled barrels but lead greatly.

|

Q. How can I make "sub-sonic" ammo?

For handguns with their small case capacity simply load a full weight bullet so the muzzle velocity is at or below 1050 - 1100 f/s. (DUH!) For rifle cartridges the problem is a little more complex. Because of the large capacity of the typical rifle cartridge case and the small charge weight volume there is a lot of empty space in the case which leads to erratic ignition and velocities. At one time special subsonic cases were made in .308 that had about half the rear of the case solid to reduce capacity and these worked much better than using regular cases. The company, Blaylock Gun Works in Texas, is apparently no longer in business.

Subsonic Ammunition Warning

The performance of subsonic rifle ammunition is highly dependent on the individual rifle, especially with loads using standard full capacity cases. Using a commercial 200 gr subsonic load, velocities ranged from 952 to 1248 f/s and bullets stuck in at least one barrel. You need to tailor the load to your particular barrel and will probably have to tap more than a few bullets out of the barrel, even using the special reduced capacity cases. If you experience a "click" instead of a "bang," or if the report sounds odd, check your bore for obstructions before firing again.

Because of the friction of jacketed bullets it is very easy to get a bullet stuck in a rifles bore with very light subsonic loads. The easiest method to get subsonic rifle ammunition is to us a full weight cast bullet and the appropriate charge, making what is basically a duplication of the old "guard" cartridges. If you have to use jacketed bullets they should be lubed either with a dry film lube or be moly-coated to reduce friction.

Some general guidelines are...

|

|

.308 Win sub-sonic load using 150 gr .30-30 flat point bullet. Bottom of case is colored and the case just above the extractor cut is knurled for positive identification. |

Updated subsonic loading data.

Experimentation has been done with IMR Trail Boss powder and the results are astounding. Trail Boss is a very bulky powder designed for the cowboy shooting crowd and their light loads. Loading is very simple--basically fill your rifle case to the base of the bullet you are using and measure that charge. Take 70 percent of that weight and use as your loading data.. For a copy of IMR's data page on this powder in PDF format click here.

Some additional loading data for conventional powders.

USE AT YOUR OWN RISK

You

use this data at your own risk. I am not responsible for any damage arising from

the use or misuse of this data.

With jacketed bullets you want to be extremely careful with velocities below about 1150 f/s as you may stick a bullet in the bore with subsonic loads unless you use moly coated bullets or lightly tumble the bullets in Lee Liquid Alox, diluted 50-50 with mineral spirits, and start with a really clean bore.

In the 5.56 the lightest load that will exit an M16 barrel reliably with M193 Ball 55-gr. bullet is 4 grs. of Unique or 3 grs. of Bullseye, which are subsonic. You must start with lightly oiled bore and wipe the bore again every ten rounds to keep from "sticking" one in the bore, as you loose all bore pressure as the bullet passes the gas port, and if you don't accelerate the bullet enough it will stick between the gas port and the flash suppressor. Loads of 5 grs. of Unique or 4 grs. of Bullseye will exit more reliably, but are louder.

In the M14 for use with the issue 12-inch twist barrel the 110-gr. FMJ .30 carbine bullet and 5 grs. of Bullseye or 6 grs. of Unique works well. You don't need to turn the spindle valve off, as the White-cutoff system doesn't bleed off all the muzzle pressure. The M80 or M118 boattail bullets do not stabilize very well and aren't very accurate at subsonic velocities in the 12-inch twist and require at least 10-inch twist. You can use a 150-gr. flatnosed .30-30 bullet with good results though, using 6 grs. of Bullseye or 7 grs. of Unique. This charge will work OK with an M80 or M118 bullet if you have a 10-inch twist. You can also use 9-11 grs. of #2400. Reportedly 6 gr (the absolute minimum load) of Red Dot and up to 7 or 8 grs will work well using 165 or 168 gr jacketed bullets.

A new arrival on the sub-sonic scene is Trail Boss powder. Originally designed for use in "cowboy" loads it is an extremely bulky powder. Loading is very simple--basically fill your rifle case to the base of the bullet you are using, weigh that charge and then use 70 percent of that as your load. For a copy of IMR's data page on this powder in PDF format click here.

For some further information on subsonic loads see the following websites.

http://members.shaw.ca/cronhelm/DevelopSubsonic.html

http://guns.connect.fi/gow/arcane1.html

http://guns.connect.fi/gow/arcane2.html

If you have a rifle in .223, .308 or .30-06 another option is to use one of the cartridge adapters available from http://www.mcace.com/adapters.htm . These will allow you to shoot .30 Mauser, .30 Luger, .30 carbine,.32 ACP, and .32 Colt/H&R in .308 & .30-06, and .22RF, .22WRM in the .223. I have played a lot with a .308 one in .32 ACP and while not as convenient as a real .308 cartridge it is very quiet and accurate and just the ticket for pot shooting or back yard pest elimination. I also had the opportunity to try one of these in a suppressed .308 rifle and the only noise was the striker falling. If they could come with a way to keep the sub-caliber rounds firmly enough in the inserts to allow magazine feeding they would be close to ideal.

|

|

Q. How effective are silencers (noise suppressors) and how do they work?

A. The effectiveness of a suppressor depends on several things. The cartridge used, the bullet's velocity, barrel length, and the design of the silencer. First of all, except in specific circumstances suppressors don't actually silence the firearm, but rather reduce the muzzle blast and change the sound of the discharged. Using a cartridge with limited powder capacity (so all or most of the powder is consumed in the bore) and with a subsonic bullet velocity (nominally about 1100 f/s) they can be amazingly quiet. Larger cartridges and those with supersonic muzzle velocities have the muzzle blast reduced substantially but the supersonic "crack" of the bullet remains. Suppressors on large caliber firearms are used by snipers not so much to quiet the blast but to make locating the source much more difficult. Contrary to what is seen in the movies most suppressors are fairly large. A typical .22RF suppressor goes about 1" x 4" long, while a .308 suppressor runs about 13/4" x 8' -10", and one for a .50 caliber rifle runs about 2" x 15".

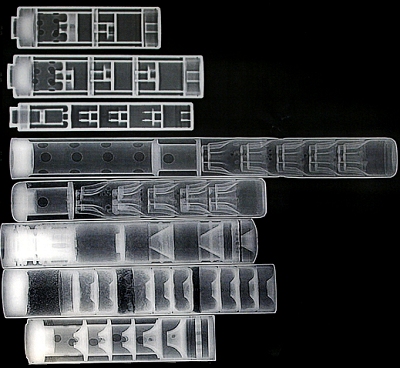

Suppressors work by slowing and cooling the propellant gases and the releasing them slowly, by means of a series of internal baffles as shown in the x-ray image below.

In the US silencers are considered "Class 3" items the same as machine guns and their purchase requires federal paperwork and the payment of a $200 transfer tax. Interestingly, in many countries with draconian gun control laws suppressors can be purchased and possessed with no paperwork or restrictions. Considering that antigunners here make a stink about the noise of shootings I'd like to see the restrictions and tax ended.

Q. How does the 6.8 SPC (6.8 x 43) cartridge compare with the current military cartridges?

A. The 6.8 mm SPC cartridge is roughly mid-way between the M855 5.56 mm and the 7.62 mm NATO rounds. It is based upon the old .30 Remington case and was designed to be more potent at all ranges than the 5.56 mm while still allowing a light, compact weapons system. It is preferred over several competing cartridges because its shape allows better feeding in automatic weapons and its size is more compatible compatible with "AR" and other 5.56 mm platforms. SAAMI specs call for a max average pressure of 55 k psi but the military loading runs around 58 k psi. It is currently undergoing field testing by regular and special operations units and is extremely well liked and has been adopted by several agencies. Comparative ballistics are given below. A 250 yard zero is assumed for all loads and velocities are based upon the GI specifications.

| M855 Ball from M4 | 115 gr OTM-E from 16" M4 | M80 Ball from M14 | 7.62 x 39 PS Ball from AK47 | |||||||||||||

| Range yd |

Ve. f/s |

Energy ft lb |

Drop in |

Path in |

Vel f/s |

Energy ft lb |

Drop in |

Path in |

Vel f/s |

Energy ft lb |

Drop in |

Path in |

Vel. fps |

Energy ft lb |

Drop in. |

Path In |

| 0 | 2970 | 1214 | 0.00 | -2.50 | 2675 | 1827 | 0 | -2.50 | 2750 | 2502 | 0.00 | -1.10 | 2430 | 1613 | 0.00 | -2.00 |

| 100 | 2592 | 925 | 2.16 | 2.62 | 2417 | 1491 | 2.60 | 3.15 | 2520 | 2101 | 2.44 | 3.59 | 2164 | 1279 | 3.18 | 4.64 |

| 200 | 2243 | 692 | 9.53 | 2.53 | 2106 | 1206 | 11.17 | 2.83 | 2302 | 1753 | 10.36 | 2.79 | 1915 | 1002 | 13.82 | 3.83 |

| 300 | 1921 | 508 | 23.87 | -4.54 | 1943 | 964 | 27.15 | -4.89 | 2094 | 1451 | 24.86 | -4.59 | 1681 | 772 | 34.00 | -6.52 |

| 400 | 1623 | 363 | 47.74 | -21.13 | 1726 | 761 | 52.37 | -21.86 | 1898 | 1191 | 47.32 | -19.92 | 1460 | 582 | 66.57 | -29.27 |

| 500 | 1347 | 250 | 84.97 | -51.09 | 1520 | 590 | 89.33 | -50.56 | 1710 | 967 | 79.47 | -44.95 | 1253 | 429 | 115.60 | -68.48 |

| 600 | 1106 | 168 | 141.65 | -100.49 | 1326 | 449 | 141.43 | -94.42 | 1530 | 775 | 123.57 | -81.92 | 1082 | 320 | 186.95 | -130.00 |

| 700 | 1001 | 138 | 226.32 | -177.88 | 1148 | 337 | 213.45 | -158.19 | 1360 | 612 | 182.59 | -133.82 | 1006 | 276 | 287.63 | -220.86 |

| 800 | 935 | 120 | 345.67 | -289.95 | 1040 | 276 | 311.80 | -248.28 | 1200 | 477 | 260.52 | -204.63 | 953 | 248 | 422.64 | -346.05 |

| 900 | 878 | 106 | 504.83 | -441.84 | 984 | 247 | 442.15 | -370.38 | 1074 | 381 | 362.70 | -299.68 | 907 | 224 | 595.98 | -509.56 |

| 1000 | 826 | 94 | 709.21 | -638.94 | 938 | 225 | 608.42 | -528.39 | 1014 | 340 | 494.78 | -424.64 | 864 | 204 | 811.74 | -715.49 |

|

|

7.62 x 51, 6.8 x 43, and 5.56 x 45 |

Typical penetration in 10 % gelatin for the above rounds are: 5.56 mm M855 - 34 cm; 6.8mm SPC - 35 cm (with the Sierra 115 gr OTM bullet); and 7.62 mm M80 - 65 cm, but there are no verified wound profiles available for the 6.8 FMJ load. Based on its ballistic with an FMJ bullet the wound profile with FMJ projectiles would be similar to the 7.62 x 39 with a shorter neck. With the Sierra 115 gr OTM (open tip match) which expands or fragments pretty well the wound profile is impressive (as are the 5.56 and 7.62 NATO with fragmenting bullets), with a 2.5' to 3" neck before fragmenting, with a total penetration of about 13 - 15 inches. (It should be noted that the Sierra 115 gr MK is not a very high BC bullet and a better design would yeild a flatter trajectory.) See the next Q&A question regarding the use of "OTM" bullets by the military. There are currently 4 variations in use: a "ball" projectile of open tip match construction with either 110 gr or 115 gr projectile, a tracer, a 97 gr AP round, and supposedly a blank round. The 97 gr AP round utilizes a solid copper bullet with bands cut around the outside and a hardened steel or tungsten penetrator inserted into the bullet. No designations are known at this time. The cartridge has performed well in barrels down to 10". Typical velocities for the SSA 115 gr commercial load are given below.

| Barrel | Velocity | Change from 16" |

|

20 |

2561 |

+36 |

|

16 |

2525 |

-- |

|

12.5 |

2384 |

-141 |

|

10 |

2265 |

-260 |

|

7.5 |

2035 |

-490 |

It should be noted that Remington commercially standardized the 6.8 SPC as a SAAMI listed round but the chamber drawing they supplied SAAMI contained an error in the chamber mouth angle and throat area that when combined with original GI spec ammunition created extremely high and dangerous pressures. Unfortunately a lot of commercial rifles have their chambers cut with the mis-dimensioned reamers. The mis-dimensions throat mouths are specified to have a 45 degree angle in the drawing actually have about a 70 degree angle when the dimensions are followed, which has caused brass shaving from the bullet and a build up in the throat area which caused pressure spikes. The original GI spec chamber and ammunition give the 2675 velocity stated above. Current commercial ammo is loaded down to about 2550 f/s from a 16" barrel in deference to the chamber problems. There has been a version "II" SAAMI chamber spec developed with basically more freebore and a large neck area, that allow full pressure GI ammunition to be fired safely but the chamber mouth angle problem still exists. The so-called "DMR" chamber, corrects the issue and allows the original full performance level the cartridge was designed for. Using the DMR chamber and a 1:11 twist barrel and 75 gr copper bullets velocities close to 3400 f/s have been achieved and with an 85 gr bullet close to 3200 f/s have been achieved from a 16" barrel without high pressures.. To view the various chamber designs click here.

A brief note about the 6.5 Grendel cartridge which was the 6.8s major contender. Careful investigation shows that many of the claimed velocities were obtained in a 20" or 24" barrel while the 6.8 velocities above are all from 16" barrels. When fired from a 16" barrel the Grendel will lose some of its claimed performance. Even using the claimed performance the difference in trajectory between a 120 gr 6.5 mm and a 115 gr 6.8 mm is minimal at 500 yards with an AR platform and a 250 yard zero. In addition, the Sierra 115 gr OTM bullet currently loaded is not the most efficient shape (G1 BC = .324) and there are currently several better designed bullets being looked at, with BCs in the high .380s to low .400s, that give drop figures equal to the 6.5 Grendel.

Q. What is the law regarding the use of "hollow point bullets" in war?

A. Some people claim that the use of "hollow point" or expanding bullets is illegal in warfare under the Geneva Convention (which is a set of international agreements to provide for "civilized" behavior between nations at war). The topic was actually addressed, but not specifically, by the Hague Accords of 1899 and 1907 which proscribed the use of "arms, projectiles, or material of a nature to cause superfluous injury" (or in some documents "unnecessary suffering") and neither term is defined. By the way, the conventions only apply to a declared war against national enemies by signatory parties. The US is not a signatory of this convention, but does abide by it.

In regards to the use of "open tip match" bullets which provide increased accuracy and which are not specifically designed to expand, the Hague Convention IV of 1907 (and NOT the Geneva Convention) does not proscribe them, nor bullets which yaw and fragment in tissue. This position was not disputed by the 1978 UNCCW Conference and was reconfirmed during its review in 1994 - 1996. Thus the US Judge Advocate General office's 1990 decision to authorized certain OTM projectiles, which yaw and then fragment just like many FMJ bullets, for unrestricted land warfare use is perfectly legal under international law and neither the nannie-state UN nor any other organization have any grounds to protest their use.

OTM ammunition is currently not more frequently used in 5.56 (as the Mk262 77 gr OTM) because it is not as widely available via the supply system and is substantially more expensive than M855, but there is a definite push to use it in all calibers., including the 175 gr 7.62 NATO M118LR and the 130 gr Mk318. The issue ball round in 6.8 x 43 (6.8 SPC) is the 115 gr Sierra MatchKing "enhanced fragmentation" OTM bullet.

If one wanted to get technical about this issue there is really no basis for proscribing a bullet that does expand, since, a) there is nothing about them that causes "unnecessary suffering;" b) an expanding bullet is simply an attempt to make a small diameter bullet create a wound channel that a larger diameter non-expanding bullet would; and c) "expanding" bullets create a less messy wound then fragmenting bullets do. In actuality this so-called "ban" is very misleading for while expanding projectiles may supposedly be proscribed, the use of mines, explosives, fragmentation, and flame weapons which indiscriminately shred and maim their victims are not.

Q. How much oil and grease should I use when lubricating my firearm?

A. Most folks over-lubricate things thinking that "more is better." There are several problems with using to much. First, excess lubricants can collect dirt and dust. Second, many lubricants can become gummy if applied too generously. Third too much lube can run and possibly deactivate ammunition in the firearm.

Especially with modern synthetic lubricants, when changing brands of lubricant, it is very important to thoroughly remove all the old lubricant and degrease the surface (91% or higher isopropyl alcohol works well) before applying the new lube. With large surfaces, after removing all the old lube thoroughly rub in several coats of the lubricant until it isn't visible and then apply a very small amount to the wear points.

With small parts just place a small amount on the contact areas and wear points. If your lube is squirting or dribbling out all over your firearm you are using too much.

Keep in mind that what/where you lubricate has a greater bearing on things than how much you put on. Beside the "normal" lube points look at your firearm and locate all the shinny spots. Those are friction points and are where the lube will do the most good.

Please email comments to Fr. Frog by clicking here.

| Back to Q&A Index | Ballistics Main Page |

| Back to Fr. Frog's Home Page |

Disclaimer

As far as I know all the information presented above is correct and I have attempted to ensure that it is. However, I am not responsible for any errors, omissions, or damages resulting from the use or misuse of this information, nor for you doing something stupid with it. (Don't you hate these disclaimers? So do I, but there are people out there who refuse to be responsible for their own actions and who will sue anybody to make a buck.)

Updated 2017-09-14